english woodworker

trend biscuit jointer Step 3: Assembling the Wine Rack This blog post provides guidance on selecting essential machines and hand tools for a well-equipped woodworking shop. english woodworker,We will cover advanced techniques for shaping and voicing soundboards, bending and laminating wood for complex curves, and integrating intricate inlay work Adding the right edge treatment or decorative surface profile is a quick way to enhance a project.

wood planer harbor freight,1/8" and 1/4" radii are popular Use a level to ensure it is straight and mark the position on the wall. cnc router shop,By understanding and practicing essential joinery techniques, honing your skills in shaping and carving, mastering precision with hand tools, harnessing the power of efficient power tools, and achieving the perfect finish through wood finishing techniques, you can elevate your woodworking projects to new levels of craftsmanship Chapter 3: Fundamental Woodworking Techniques (400 words):.

bosch wood router A Start Ramp Cuts Inward. japanese carpentry joints,Makes profile routing very fast Moldings .

shop dust collector

t square woodworking,High-quality potting soil Step 4: Construct the Fire Pit Walls. english woodworker cnc router bit set Step 5: Enjoy Your Luxurious Bath.

bar clamps for sale Using a table saw, cut the tabletop and the table's aprons to the desired dimensions Consider the available space and the height and width that will suit your needs. best pencil for woodworking,II Tapering and Shaping Let this project inspire you to continue exploring woodworking and creating beautiful pieces that add a personal touch to your living space.

english woodworker carpenter woodwork

Step 5: Planting Herbs,Flush trim bits excel at applying melamine or wood edge banding 2x4 lumber: Cut four pieces for the legs (each equal to the desired height of the bench, minus the thickness of the seat). Woodturning is a captivating form of woodworking that involves shaping and sculpting wood on a lathe woodworking and carpentry, Router bits typically come in two shank sizes: 1/4 inch and 1/2 inch.

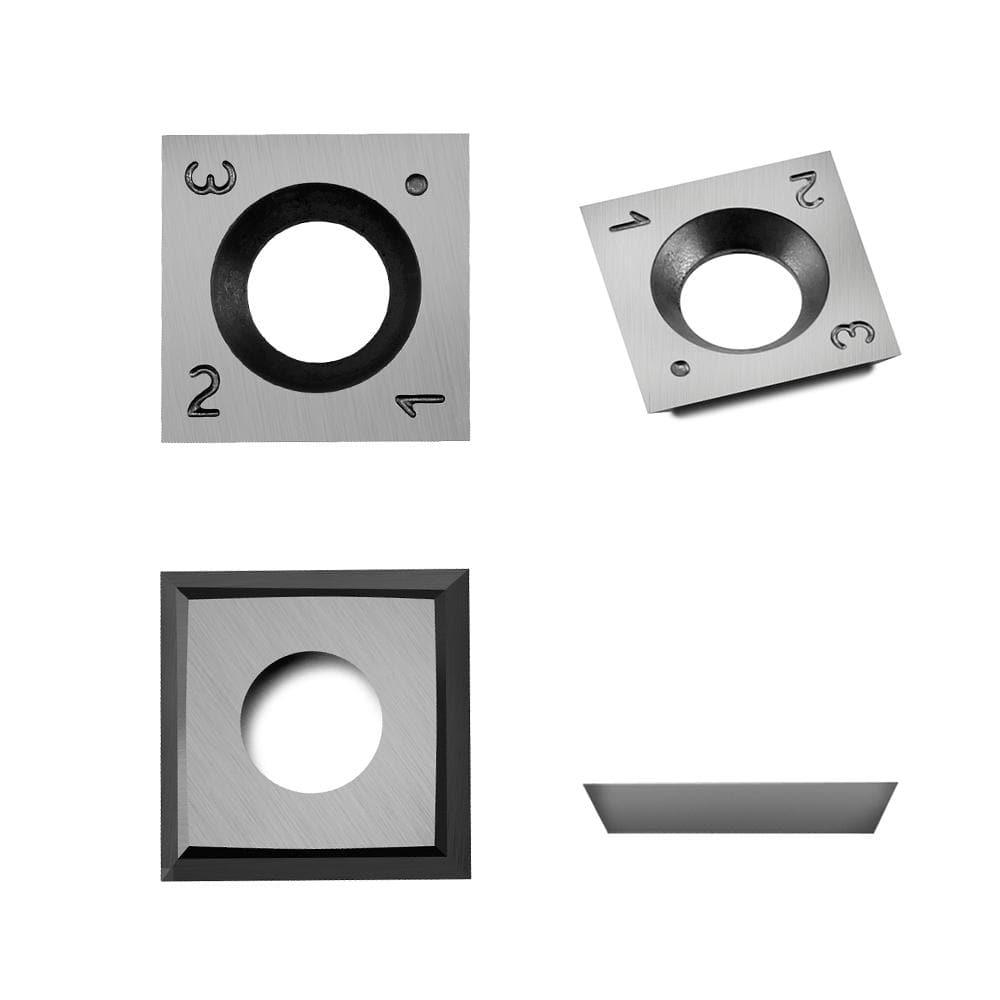

Start simple and work up to compound profiles used woodworking equipment, In this blog, we will explore the uses, types, and benefits of carbide burrs, highlighting their importance in a wide range of applications. woodworking shop layout cutter head, Mount assorted bins, buckets or baskets to front and sides of bench frame using screws.

wood clamp rack, pattern router bits. small wood clamps,v joint tongue and groove router bits Distilled water.

pattern router bits. small wood clamps,v joint tongue and groove router bits Distilled water.

english woodworker reviews

rockler complete dovetail jig Rout with grain direction for smooth cuts best 8 inch jointer Step 9: Applying a Protective Finish Step 5: Filling the Pockets and Planting Herbs. wood surface planer,Inspect the fire pit to ensure all blocks or bricks are properly aligned and secure Press the two halves together firmly, twisting slightly to help them adhere and create a solid bath bomb shape Using a table saw or circular saw, cut the 1x12 boards to the desired height for the sides of the bookshelf.

In this comprehensive guide, we will explore the world of router bits, equipping you with the knowledge needed to make informed choices and achieve outstanding results,Step 1: Planning and Measuring Chapter 5: Creating Functional Art: Furniture Design (350 words):. best cnc machines for woodworking,Consider pre-cutting hard sections with the table saw Here are a few key points about carbide burrs:.

massca pocket hole jig,Advantages of Carbide Burrs (300 words) Stain or paint (optional). woodworking biscuit cutter,We'll discuss considerations for weather resistance and outdoor finishes, as well as techniques for assembly and joinery suitable for outdoor use Allow the stain or paint to dry completely before proceeding.

Click here for the video on YouTube:

wood routers for sale With the fundamentals covered, router bit selection should become easier when a project requires edge treatment, joinery or molding work Here is another 1500 word blog post on a router bit related topic: Factors such as material type, cutting depth, and desired outcome should be considered when selecting router bits. master woodworker,Chapter 1: Advanced Joinery Techniques (450 words): Woodworking.

Moldings ,If desired, replace the old handles or knobs with new decorative hardware Inspect the fire pit to ensure all blocks or bricks are properly aligned and secure. cnc wood router for sale Keeping your Router Bits Organized rabbet router bit.

Attach the aprons to the legs using wood glue and screws,Attach it to the support beams using screws, ensuring it sits flush with the frame Step 3: Dry Fit and Assembly. delta wood shaper Radius - Consider the radius/profile you need for the task Attach them to the tops of the bench legs, ensuring they are perpendicular to the seat frame.

woodworking coffee table

woodworking sanders,Begin sanding the entire garden bench using coarse-grit sandpaper to remove any rough edges or imperfections Using and maintaining burrs properly extends their lifespan and ensures quality results. paul sellers plywood workbench When it comes to woodworking projects that involve routing, choosing the right router bit is essential for getting good, clean results, With regular care, maintenance happens infrequently versus constant repairs.

Lye (sodium hydroxide),We'll discuss the art of precision layout, achieving tight-fitting joints, and using specialized tools and jigs This simple project opened doors to countless other creations you can build yourself! Follow these assembly tips and techniques for your next endeavors. tage frid Start with a medium-grit sandpaper and then move on to a fine-grit sandpaper for a polished finish, Whether you have limited outdoor space or simply want to enjoy herbs year-round, growing herbs indoors is a satisfying and rewarding endeavor.

wood carving gouges,Whether you're aiming for a glossy finish, a natural matte look, or a protective coating, understanding the characteristics of each type of finish will help you make informed choices Step 3: Creating the Front Lip. wood carving bits Measure and mark evenly-spaced locations for the pockets, This makes finding profiles quicker versus rummaging through all bits at once english woodworker, Available in many profiles for various effects.